From initial design to cleanroom assembly, our vertically integrated capabilities allow us to deliver end-to-end plastic solutions that meet the demanding standards of aerospace applications.

Elevating Aerospace Standards with Precision Welding

One of our aerospace clients faced challenges with the durability and lightweight requirements of cockpit windows and fuel tanks. By utilizing our advanced plastic welding techniques, we were able to deliver high-performance components that met the stringent regulatory standards and exceeded the client’s expectations in terms of durability and weight reduction. This success not only enhanced the client’s product quality but also significantly improved their manufacturing efficiency.

Comprehensive Aerospace

Welding Solutions, Delivered

at Scale

How much time do you spend addressing issues with your production equipment? How much productivity is lost due to subpar welding techniques or faulty components? Foxx Technologies can help you overcome these challenges and maximize your operational efficiency.

Our specialized service technicians can be on-site when needed, managing installations and maintenance. We ensure the job is done right the first time, equipping your company with cutting-edge welding solutions that seamlessly integrate into your aerospace manufacturing processes.

Services for Aerospace Industries

Our aerospace solutions offer enhanced durability, lightweight materials, regulatory compliance, cost efficiency, and customized solutions for optimal performance and reliability.

Plastic Designing

CAD/CAM engineering for lightweight and durable aerospace parts

Design for manufacturability (DFM) to ensure efficiency and cost-effectiveness

Material recommendations for high strength, flame retardancy, and thermal stability

Prototyping

Rapid prototyping of aerospace components to accelerate R&D and testing

3D printing and CNC models for fast design iterations

Proof-of-concept samples validated to aerospace requirements

Plastic Molding

Precision injection molding for consistent, high-tolerance parts

Capability for small batch or large-scale aerospace production

Advanced polymers and specialty resins compatible with aerospace standards

Plastic Machining

CNC machining of complex geometries and tight-tolerance parts

Milling, turning, and drilling for high-performance aerospace components

Surface finishing and polishing to ensure durability and compliance

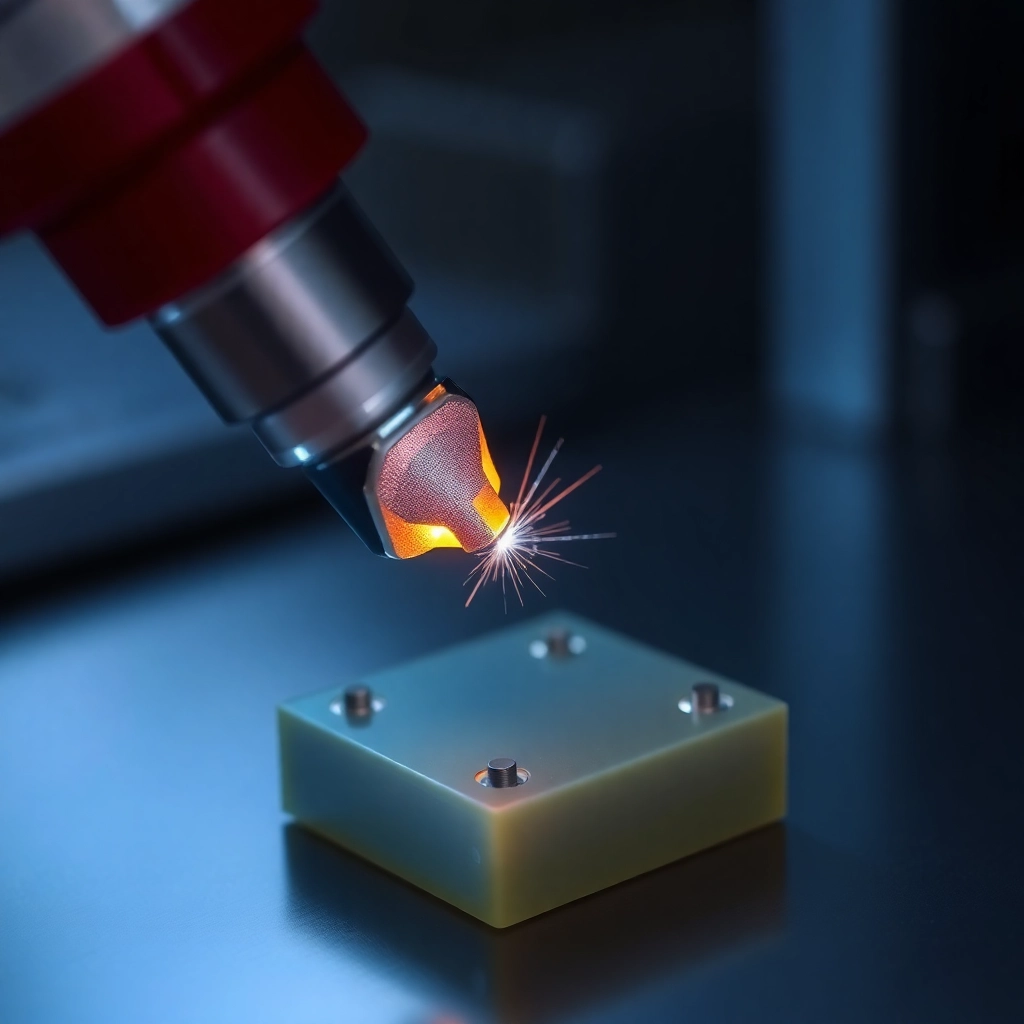

Plastic Welding

Advanced welding techniques for strong, reliable joints in aerospace parts

Methods include ultrasonic, laser, and hot-plate welding

Ensures leak-proof and structurally robust assemblies

Cleanroom Assembly

ISO-class cleanroom facilities for critical aerospace sub-assemblies

Controlled environment for contamination-sensitive components

Full assembly, testing, and packaging to aerospace industry standards

Why Choose Foxx Technologies

- Experience across regulated industries: supporting critical applications where precision and compliance are non-negotiable.

- Material expertise: fluoropolymers, high-performance resins, and aerospace-grade plastics.

- End-to-end support: from design concept through full-scale production and assembly.

- Scalable manufacturing: pilot runs to global production volumes.

Types of Welding

Services in Aerospace

Foxx Technologies employs a variety of advanced welding techniques to meet the diverse and specialized requirements of the aerospace industry.

Ultrasonic Plastic Welding

Ultrasonic plastic welding is perfect for creating rapid, high-strength bonds in small, delicate aerospace parts. This advanced method meets the aerospace industry's stringent requirements for lightweight, durable, and precision-engineered components, ensuring reliability and performance in critical applications.

Hot Gas Welding

Hot gas welding, or hot air welding, uses a specialized heat gun to produce a jet of hot air that softens the parts to be joined and a plastic filler rod, all made of similar materials. This method creates durable, precise bonds, ideal for aerospace applications requiring strong plastic joints.

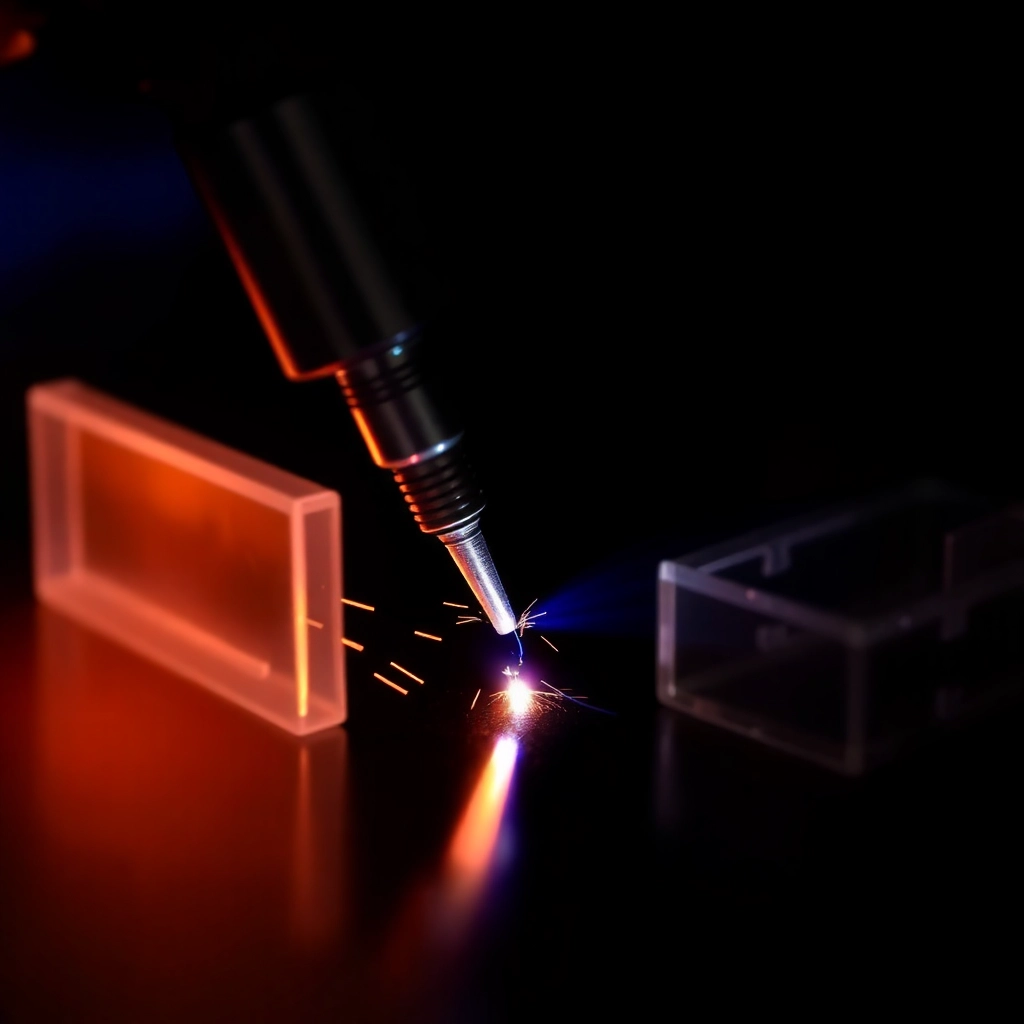

Laser Welding

Laser welding is ideal for high-precision aerospace applications, requiring minimal thermal distortion. This advanced technique harnesses focused laser beams to create exceptionally strong and accurate bonds in plastic components, ensuring the integrity and performance of lightweight, intricate aerospace parts.

High-Frequency Welding

High-frequency welding is highly effective for joining thermo-sensitive aerospace components, ensuring robust and durable bonds under stress. This technique uses electromagnetic fields to generate heat, creating strong, reliable seals without compromising the material's integrity, making it perfect for demanding aerospace applications.

Solvent Welding

Solvent welding is crucial for aerospace applications where a strong, seamless bond is essential. This method uses solvents to dissolve the surfaces of plastic components, allowing them to fuse together, resulting in highly durable and reliable joints suitable for critical aerospace parts.

Our Comprehensive Solutions in Aerospace Industries

Plastic Welding

Plastic welding is vital in aerospace for producing components such as cockpit windows, fuel tanks, and ducts. Our advanced plastic welding services ensure high-quality bonds and seamless integration, meeting the stringent standards of the aerospace sector.

3D Printing

Leverage our cutting-edge 3D printing for rapid prototyping and production of highly customized aerospace parts. This service enables quick innovation, precision, material versatility, and reduced lead times and costs.

Plastic Machining

Specializing in aerospace plastic machining, we provide precision-engineered components tailored to industry needs. Our advanced processes ensure the production of complex parts with high accuracy, optimal performance, and reliability.

Plastic Molding

Our plastic molding services tackle complex aerospace challenges, delivering reliable and intricately designed components. Our techniques optimize manufacturing costs and ensure consistent quality and performance.

Design and Consulting

Our design and consulting services offer expert guidance to enhance functionality, streamline manufacturing processes, and ensure regulatory compliance. We collaborate closely with clients to optimize product designs specific to aerospace requirements.

Enhance Productivity While Cutting Costs

With our comprehensive aerospace welding solutions, we handle all the complexities for you. No more valuable time spent troubleshooting or coordinating with multiple vendors when production issues arise. Trust Foxx Technologies to keep your operations running smoothly and efficiently.