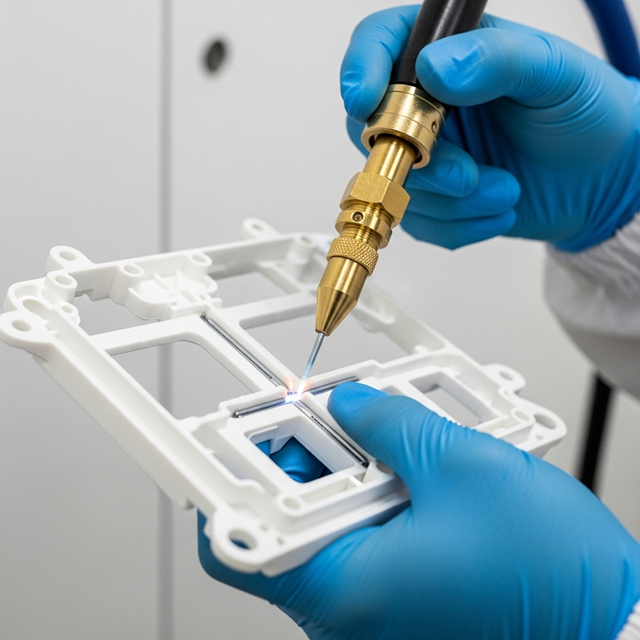

Plastic Welding Services

At Foxx Technologies, our advanced plastic welding capabilities ensure permanent, particle-free, and high-strength seals across a broad range of thermoplastic components used in Aerospace, Industrial, Automotive, Defense, Electronics, and Retail applications.

Our process is designed to meet the most demanding requirements where leak-proof performance, structural integrity, and precision are critical.

Plastic Welding Service Types

Comprehensive plastic welding solutions for your most demanding applications.

Extrusion

Welding

Hot Gas

Welding

Speed Tip

Welding

Cleanroom-compatible

Welding

World's Leader in Precise Plastic Welding Technologies

At Foxx Technologies, we ensure the durability, precision, and reliability of our welds through extensive testing and validation processes tailored for Aerospace, Industrial, Automotive, Defense, Electronics, and Retail sectors.

Our rigorous quality assurance protocols guarantee that every weld meets the highest standards of performance, safety, and longevity required by mission-critical industries.

Our tests are designed to:

Assess strength and durability under extreme conditions:

Validation of weld integrity across aerospace-grade specifications and defense requirements.

Simulate real-world applications to identify potential failure modes:

Proactive identification and elimination of potential weak points before production.

Optimize weld performance for long-term reliability:

Ensuring consistent quality and extended service life across all industrial applications.

Cleanroom-compatible welding in Class 7 validated environments:

Full compliance with cleanroom protocols ensuring contamination-free, precision welds.

Our Expertise with Custom Plastic Welding

Precision plastic welding services accelerate product development from initial design to production-ready components.

Advanced Ultrasonic

Welding

High-precision joining for complex plastic assemblies requiring clean, strong, and reliable welds performance assurance.

Precision Fixturing &

Assembly Integration

Custom tooling and fixtures engineered to maintain part alignment and repeatable weld quality control measures.

Hot Plate & Infrared

Welding Capabilities

Ideal for large, thick-walled, or geometrically challenging components needing uniform heat distribution.

Strength, Leak, & Seal

Integrity Testing

Robust validation protocols ensuring every welded joint meets mechanical, pressure, and durability standards.

Laser Welding for

High-Clearance Applications

Non-contact, particulate-free welding for assemblies demanding tight tolerances and minimal thermal distortion.

Filtration Systems

Welding

Scalable welding solutions supporting low-volume prototypes through high-volume production environments.

Industries We Serve

Specialized plastic machining services across mission-critical industries where precision, reliability, and quality are paramount.

Aerospace

Foxx Technologies delivers lightweight, high-performance plastic components for aerospace systems. Our precision molding, advanced engineering, and cleanroom assembly meet strict aviation standards, ensuring safety, reliability, and compliance across every mission-critical application.

Defense

Foxx Technologies delivers high-performance plastic components for defense systems. Our design, molding, and cleanroom assembly ensure durability, reliability, and compliance. We specialize in machining, welding, and prototyping built for mission-critical performance and safety.

Industrial

Foxx Technologies delivers high-quality plastic components for industrial systems. Our CAD-based design, precision molding, and cleanroom assembly ensure scalable, reliable outcomes. We specialize in machining, welding, and prototyping built to meet strict industrial standards.

Electronics

Foxx Technologies delivers high-quality plastic components for electronic systems. Our design, molding, and cleanroom assembly ensure performance, safety, and compliance. We specialize in machining, welding, and prototyping built to meet strict electronic standards.

Automotive

Foxx Technologies delivers precision plastic components for automotive systems. Our design, molding, and cleanroom assembly support scalable production and performance. We specialize in prototyping, welding, and machining—engineered to meet strict automotive standards.

Retail

Foxx Technologies delivers high-quality plastic components for retail systems. Our design, molding, and cleanroom assembly ensure durability, consistency, & compliance. We specialize in machining, welding, & prototyping built to meet retail standards for packaging & product innovation.

Trusted by Industry Leaders

Trusted by industry leaders for global manufacturing, cleanroom production, and expert in-house design.

USA & India-based Manufacturing

Global manufacturing capabilities with local supports

Cleanroom-Compatible Production

Manufacturing environment suitable for critical applications

In-house Design & Engineering

Complete design and engineering capabilities

Ready for Your Next Project?

Schedule a meeting for your plastic design project. Our experts are ready to help with custom solutions tailored to your specifications.

Benefits of Plastic

Welding

Plastic welding for manufacturing has many benefits, hence its application in several industries and rapid prototyping. Below are a few benefits:

Additional Consumables

There is no need for extra consumables such as fasteners, solvents, or glues. Therefore, there is a reduction in complications, risks, and costs accrued due to extra consumables.

Compatible with any Joint Shape

The process is suitable for parts of any shape. Development in the different welding techniques has made it possible to work with complex shapes. Therefore, you can weld parts with curved or irregular shapes with ease.

No Need for a Ventilation Environment

Some welding techniques used for plastics don’t produce fuses, e.g., vibration-based welding. Therefore, there is minimal need for protective gears and infrastructure that aids ventilation.

Cost-Effective Option

The technique requires a low need for consumables and a low cycle time. Therefore, it is more effective than other joining methods such as riveting.

Highly Versatile Welding Choice

It is suitable for parts of any size or dimension. This is unlike other joining methods. For example, riveting requires the parts to have a minimum size depending on the rivet. So, the only thing required is to find the most suitable one among all techniques for welding plastic parts.

Lighter than Using Mechanical Fasteners

Welding plastics do not require many consumables. Consequently, this reduces the weight of the final welded products, unlike other methods that use mechanical fasteners and rivets contributing to the overall weight.

The Weld is Permanent

The welded joint is permanent, in contrast to adhesives or other plastic joining mechanisms. Therefore, it is a reasonable choice when you don’t want the internal component to be compromised.

Applications of Plastic Welding

Plastic welding parts have a wide range of applications across various industries. Foxx Technologies provides specialized welding services in the following sectors:

Aerospace

Foxx Technologies provides plastic welding services for the aerospace industry, manufacturing critical aircraft components including cockpit windows, fuel tanks, and ducts. Our precision welding ensures durability and performance, meeting the stringent standards of the aerospace sector.

Automotive

Plastic welding is crucial for manufacturing various automotive components such as fuel tanks, bumpers, dashboard components, and door panels. Foxx Technologies provides specialized welding services to ensure these parts are high-quality and durable, meeting the rigorous demands of the automotive industry.

Industrial

Plastic welding is essential for producing a wide range of industrial components, including storage tanks, piping systems, and machinery parts. Foxx Technologies delivers specialized welding services to ensure these components are robust and reliable, aligning with the stringent requirements of the industrial sector.

Electronic

In the electronics industry, plastic welding is used to create protective enclosures, circuit board holders, and various electronic housings. Foxx Technologies provides specialized welding services to ensure these components meet high standards of precision and durability, crucial for sensitive electronic applications.

Military

In the military sector, plastic welding is vital for manufacturing durable and high-performance components such as equipment casings, ammunition storage, and vehicle parts. Foxx Technologies offers specialized welding services that ensure these components meet stringent military standards for durability, reliability, and performance.

Ideal Plastics for Welding Applications

There are many plastics options on the market that are ideal for your varying challenges. Plastic welding services are typically performed using these polymer-based materials:

Polytetrafluoroethylene

is resilient, stable and features the ability to withstand exposure to harsh chemicals. Consider this as an alternative to metal piping you may using.

Metal brazing

involves something called capillary action, which is the melting of a filler metal at a low temperature to join two base metals.

Polypropylene

is known for its elasticity and high chemical resistance. This plastic is often seen in consumer product packaging, and is also used for projects in the textiles industry.

Chlorinated polyvinyl chloride

is known for its ability to withstand high temperatures. It’s often used for hot- and cold-water piping as well as industrial liquid handling.

Polyvinyl chloride

is a lightweight, rigid plastic known for its strength and fire retardant properties. It can be used in many of your construction projects.

Polyvinylidene fluoride

is a durable, strong plastic known for its ability to withstand harsh chemicals. We have used it as a solution for our clients in the medical device and semiconductor industries.